North Burnett Horticulture Farm

Energy Savings: 38% | Cost Savings: $23,291 | Capital Cost: TBC | CO2 Savings: 50 tCO2-e | Project Status: Proposed

Industry:

Horticulture

Location:

Wide Bay Burnett

Pump Type:

Turbine

Irrigation Type:

Drip

Technology:

Solar Power and Renewables, Variable Speed Drives

This avocado farm in the North Burnett consumed 179,808 kWh of power at its main irrigation shed at a cost of $45,349. The farm’s electricity tariff is Ergon’s Small Business Retail 22C.

The farm’s pumphouse has two vertical turbine pumps (32kW and 37kW) that operate in parallel under all pumping scenarios. The pumps are controlled by Variable Speed Drives (VSD) to control the pump’s speed depending on the blocks to be irrigated or if the water pumped to the dam.

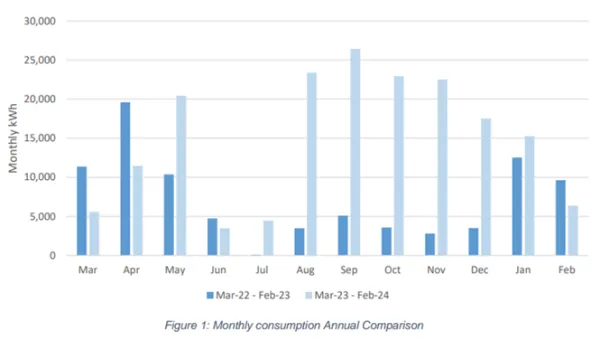

The electricity consumption at the site is highly seasonal and varies year-to-year depending on rainfall. The monthly electricity consumption for the irrigation shed over two years is shown in Figure 1 to highlight the variation.

Solar PV System

The farm had installed a 62 kW (with 50kW inverter) ground mounted solar system that utilises micro inverters on each panel to maximise generation.

The site is not eligible for a feed-in-tariff (FiT) as the inverter size is greater than the prescribed 30kVA, and the site has become a large energy user, consuming more than 100,000kWh of electricity per year.

The auditor found that there had been extensive periods when the solar system was not functioning. At the time of the audit, one section of the system was not working (about 1/6 of the array) and other panels were showing reduced output.

Based on modelling of the potential solar generation and the actual use of pumps, it was estimated that around 60% of the site’s solar power is used on site with around 40% being exported at $0 return to the farm.

Electricity Tariff Review

Given the current consumption, it is expected that the site will be changed to a large electricity customer. It was estimated that moving the site to a large customer demand tariff, Tariff 44, would increase costs by approximately $13,000 per annum based on the previous year's irrigation.

Therefore, the primary focus for this site’s energy assessment was to find ways to reduce demand and maximise the utilisation of the solar system, and ensuring the pumping is operating at the optimal efficiency.

Irrigation System

The energy auditor found that even though VSDs were installed at both pumps, the farm's irrigation system was operating at an average energy consumption of 7.7 kWh/ML/m head, higher than a target consumption of 4kWh/ML/m or less.

The energy assessor found a number of issues on site that are likely to contribute to the higher energy consumption including:

- heavy throttling of one of the pump’s outlet pipes with a gate valve

- running pumps close to maximum for transfer pumping to the site’s main dam when not irrigating

- sections of pipe where piping configurations lead to inefficiencies with elbows and narrow pipes leading to friction losses

- an old impellor at the site showing damage which may be caused by cavitation or debris.

Irrigation System Issues can be seen below: Gate valve partially closed (left), inefficient pipe configuration (centre) and old, damaged impellor (right).

Key Recommendations

Accordingly the audit recommended a number of measures that are likely to have a low capital cost to make significant energy reductions including:

- shift pumping to fit more within solar generation times

- fix the damaged section of solar panels (potentially under warranty).

- check additional poor performing panels (potentially under warranty).

- open the gate valves throttling pump 2 to reduce friction losses.

- reduce the pump speed to 80% for transfer pumping and extend the pumping time for the volume required (and adjust speed to suit solar generation).

- shift pumping times to coincide with lower cost Tariff 22C times while the tariff is available.

- shift usage from the peak times during weekdays to day-and-night periods. The estimated savings were calculated as $5,853 per annum.

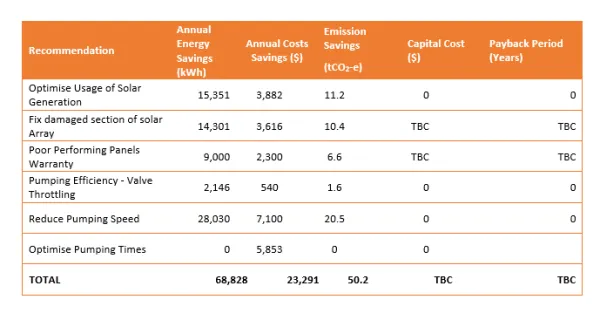

The costs and benefits of implementing the recommendations are shown at Table 1.

Table 1. Summary of Recommendations.

The audit also recommended reviewing a number of aspects of the irrigation system but did not provide cost estimates for these including:

- Checking pipe configurations and adjusting where suitable, removing unnecessary bends to reduce friction losses.

- Check the cause of the damage to the previous impellor to determine whether the cause of damage remains and whether it can be resolved with improved pumping efficiency.

Conclusion

The audit identified six energy and cost saving opportunities for the farm that are likely to achieve significant annual savings of 68,000 kWh of electricity with associated greenhouse gas emissions of around 50 tCO2e and $23,000 of electricity costs

Energy Audits.

The farm had a Type 2 energy audit as a participant in the QBEST Ag program.

The program is being delivered by the Queensland Farmers’ Federation and is funded by the Queensland Government.