Gayndah Citrus Plantation

Energy Savings: 60% | Cost Savings: 55,562 | Capital Cost: NA | CO2 Savings: 189 tCO2-e | Project Status: Proposed

Industry:

Horticulture

Location:

Wide Bay Burnett

Pump Type:

Not applicable

Irrigation Type:

Micro irrigation

Technology:

Irrigation and Pumps, Tariffs, Solar Power and Renewables

A Type 3 Energy Audit was conducted at a pump station on a 100 hectare Gayndah citrus farm. The farm produces a range of citrus varieties with around 38,000 trees across 20 blocks. The plantation requires irrigation all year round with a peak period during the summer.

The pumps operated for 3,300 hours in the year before the audit, consuming over 350,000 kWh with a higher proportion consumed during the summer.

Irrigation Pumps

The irrigation system at the Citrus farm uses two Southern Cross 150x125 – 400 mixed flow pumps connected in series to achieve the required system pressure, irrigating the farm in 11 shifts. Each of the shifts have a different area with a different number of trees, and therefore different water flow rate requirement.

The river pump at the citrus plantation achieved peak electricity usage at 5.31 – 6.52 kWh/ML/m head, while the boost pump achieved 4.63 – 5.33 kWh/ML/m head depending the shift. The assessment highlighted that both pumps are working outside the efficient range on the manufacturers pump curve.

A benchmark for pump efficiency is the target electricity usage of 3.80kWh/ML/m head.

Recommendations

Three key Energy management opportunities were identified to reduce energy usage and cost.

Tariff Change

The farms was billed as a Large User on Ergon’s Large Business Tariff T45. The Auditor suggested a change to T44, which would reduce power costs by $9,560.76 based on consumption for the 12 months prior to the audit.

Irrigation System Design

The audit recommended to continue engaging a Certified Irrigation Designer to comprehensively check and redesign the current irrigation system.

Analysis indicated that a single pump with a variable speed drive may be sufficient to meet the pumping requirements, reducing the energy consumption by 92,018.5kWh (25.7%) and demand by 27.9kW. The VSD would allow the pump to adjust to the variation in shifts.

The project capital expenditure for the pump station upgrade was estimated at $152,752 which provides a payback period 7.7 years with an ROI of 12.9 % based on Tariff 44. This analysis highlights a 25.7% energy savings with a 16.6% cost savings.

100kW Solar PV System

The auditor considered a number of options for a solar system for the site, including a 60kW, 80kW and 100kW system.

The comparison at Figure 1 shows how much energy from each system would be utilised on site (Solar Offset) and exported to the grid. It also shows how much electricity would still be required from the grid (Grid Import). The most cost-effective system will reduce Grid Import and maximise Solar Utilisation (Solar Offset) with a smaller proportion of export.

A 100kW solar system was recommended because it offers the most suitable utilisation, reducing electricity consumption by 122,818kWh. It is predicted the energy costs will reduce by $24,264.88 on SAC Large Tariff 44 with a 4.3-year simple payback period, a 23.2% return on investment.

The auditor noted that the solar analysis is based on the current pump set up and recommended upgrading the pump first, then reassessing the potential for solar power once the farm has gathered data from the new pump. The new pump will reduce energy consumption significantly and may allow the use of the pump to be adjusted to pump more during solar generation times, improving utilisation.

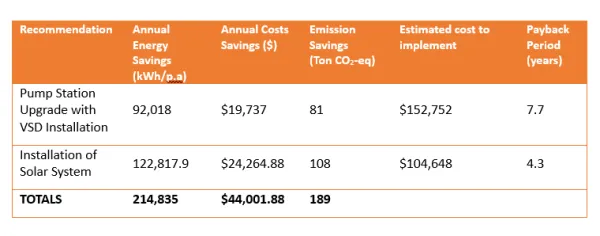

The details of the expected implications of the recommendations, if implemented, are summarised in the table below.

For more information about Choosing Solar Systems, see the Ag Energy Hub Solar Article HERE.

The program was delivered by the Queensland Farmers’ Federation and funded by the Queensland Government.