Daintree Salt Water Barramundi

Energy Savings: 65% | Cost Savings: $102,835 | Capital Cost: $258,000 | CO2 Savings: 0 | Project Status: Proposed

Industry:

Aquaculture

Location:

Wet Tropics

Pump Type:

Centrifugal

Irrigation Type:

Not applicable

Technology:

Irrigation and Pumps, Demand Management, Power Factor Correction, Solar Power and Renewables, Variable Speed Drives

Daintree Salt Water Barramundi is a North Queensland barramundi producer with 14 production ponds and a tourism enterprise. The farm is an energy intensive enterprise, using over 500,000 kWh per year. The farm operates 24/7.

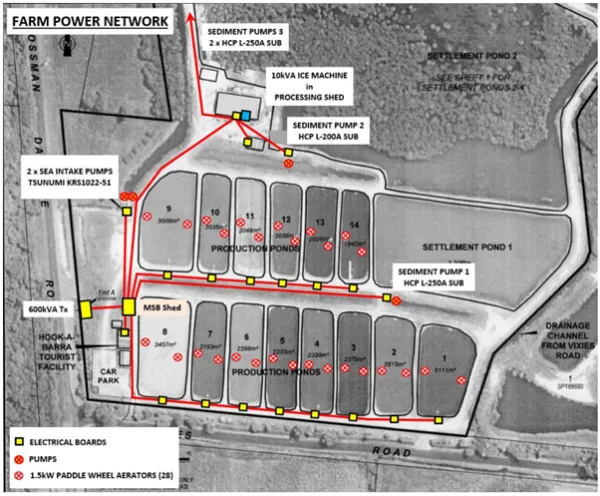

One of the main energy users at the site is the pond aeration, consisting of 2 paddle-wheels in each production pond, shown in the farm plan below.

The energy assessment made a number of recommendations including:

- Considering an alternate energy retailer

- Voltage Optimisation

- Variable Frequency Motor Drives

- Power Factor Correction

- A Solar system.

Adding a Variable Frequency Drive (VFD) to the 22kW sea pump will reduce the starting current, and allow the motor to be run at 80% which will reduce demand by 7kVA and consumption by 17,120kWh, reducing energy costs by $5,394.

A variable speed drive could be added to each pair of aeration motors which would save over 107,000 kWh per year, reducing demand by 14kVA and saving $49,000 in annual energy costs.

Installing a power factor correction unit would reduce demand by between 24 and 32 kVA per month reducing costs by $7,200, with a capital cost of $16,500 and a simple payback period of 2.3 years.

Finally, adding a 100kW Solar PV system, would produce 164,000 kWh per year of power, saving around $31,500 per year. The system has been sized to maximise solar utilization as the site is not eligible for a feed in tariff for exported power.

All of the projects identified in the audit had a total cost of $258,050 and an annual saving of $102,835, giving a simple payback of 2.5 years when combined, with the payback periods for individual projects ranging between 0 and 4.8 years.

The Case Study is featured in the Aquaculture Efficiency webinar presented by Alan Day who was the auditor for the site. Watch the Webinar on the Ag Energy Hub HERE. The webinar provides useful background information on voltage optimisation, power factor and how variable speed drives work.

Energy Audits. The farm had a Type 2 energy audit as a participant in the QBEST Ag program.

For more information about Choosing Solar Systems, see the Ag Energy Hub Solar Article HERE.

The program was delivered by the Queensland Farmers’ Federation and funded by the Queensland Government.