Ayr Nursery

Energy Savings: 453% | Cost Savings: $6,822 | Capital Cost: $30,668 | CO2 Savings: 53.9 | Project Status: implemented

Industry:

Nursery and garden

Location:

Dry Tropics

Pump Type:

Bore

Irrigation Type:

Boom

Technology:

Solar Power and Renewables

The farm consists of 0.73 ha irrigated from January to October producing around 100,000 units per ha per year. Energy consumption varies with seasons, being higher in winter, with peak demand during seeding and tray washing operations. Most production processes are labour intensive with packing and plant movement done by hand.

The annual energy consumption for the site during the 2018-2019 period was 10,115 kWh at a cost of $3,095. As the nursery is planning to install a 60-kW steam generator and steam chamber to disinfest growing and transport containers for biosecurity purposes, electricity requirements are expected to increase by 78% and costs by 68%.

The energy consumption on the farm consists of:

- Irrigation: several bore pumps.

- Propagation: includes seeding line (vacuum pump, tray filler, compressor, conveyor, mixer), germination room (air conditioning/ environmental control), seed storage (tray leveller and brush, air conditioning/ temperature control).

- Office: includes a large air conditioning, several computers and screens, and a security system.

- Staff facilities: air conditioning and refrigerator.

- Other minor uses: including growing areas, despatch, and workshop.

A recent energy audit showed how improving the current systems can lead to energy and cost savings. The audit recommended to install:

- A 22kW Roof Mounted Solar PV: to offset the potential increase in electricity due to the steam sterilisation system and reduce energy consumption from the grid. To ensure the effectiveness of the measure, the auditor recommended installing a timer on the steamer to control the operating hours by matching them with solar generation.

The auditor also identified immediate no cost or low-cost measures as follows:

- Activate energy-saving settings in the office and staff facility equipment or install automated timers to turn off equipment out of hours, which can help save energy consumption by 10-20%.

- Purchase energy-efficient replacements when required, including lighting and appliances.

Table 1. Costs and savings from audit recommendations.

| Recommendation | Annual Energy Savings (kWh) | Annual Costs Savings ($) | Emission Savings

(tCO2-e) |

Capital Cost ($) | Payback Period (Years) |

| 22 kW Solar PV | 35,832 | 4,335 | 29 | 30,668 | 7.1 |

In addition to the steam sterilisation system, the grower is planning to install a new bore pump, two large climate-controlled greenhouses, a control computer, fertigation systems, and chemical application systems, to support the planned production increase over the next 5 years, which will considerably increase the electricity demand on-farm. Based on that, the nursery has proceeded with the implementation of a Roof Mounted 30 kW Solar PV.

The savings made have been measured in a Measurement and Verification (M&V) process, as outlined in Table 2.

Table 2. Estimated and Actual energy and cost savings.

| Metric | Audit estimation | M&V calculation | Variation (%) |

| Energy Savings including exports (kWh) | 35,832 | 66,551 | 86 |

| Cost Savings including exports revenue ($) | 4,335 | 6,822 | 57 |

The greater savings achieved compared to the estimated have been influenced by the larger system implemented. No additional factors have been identified, such as higher solar radiation during the measurement period or optimization of the orientation of the panels.

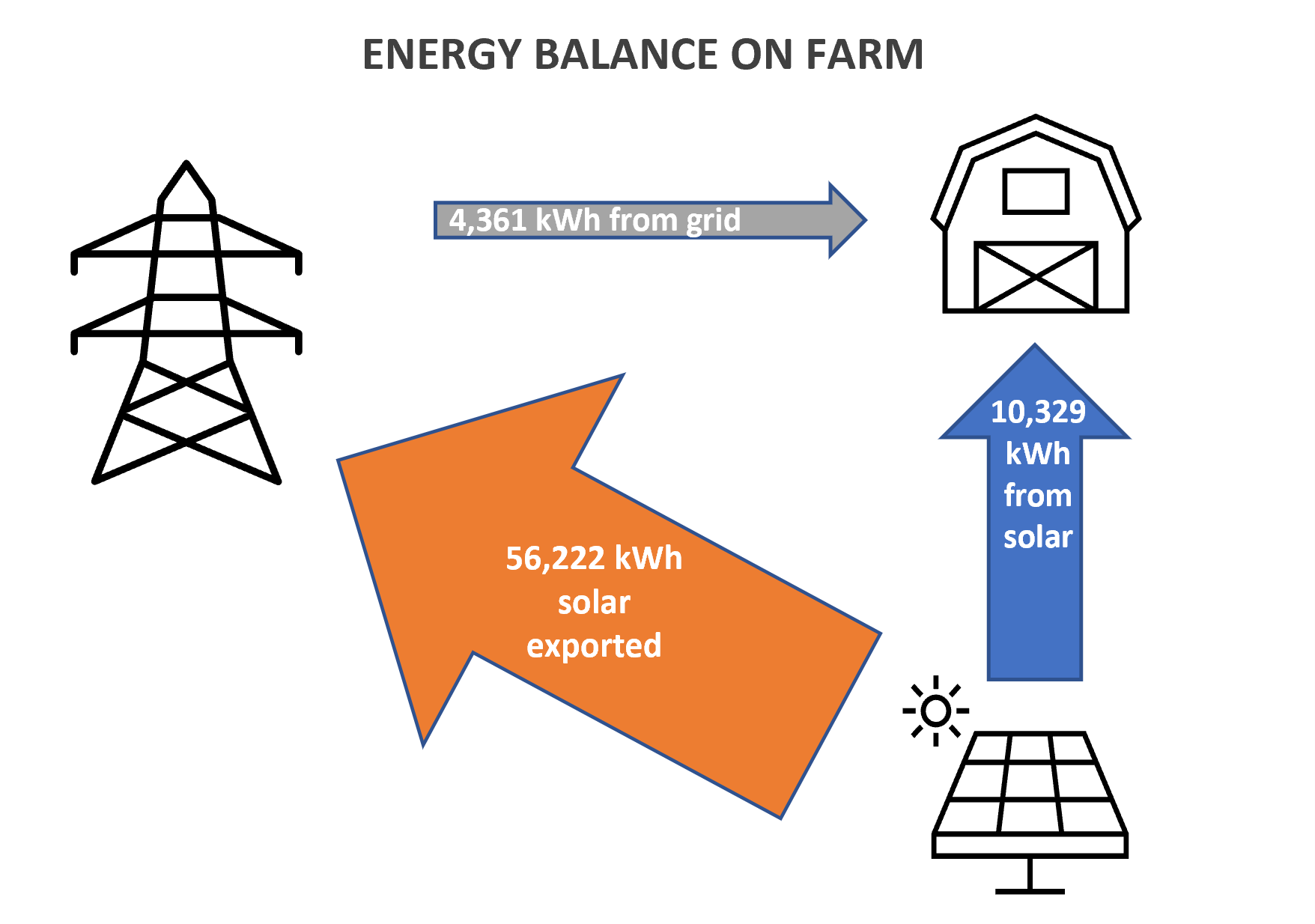

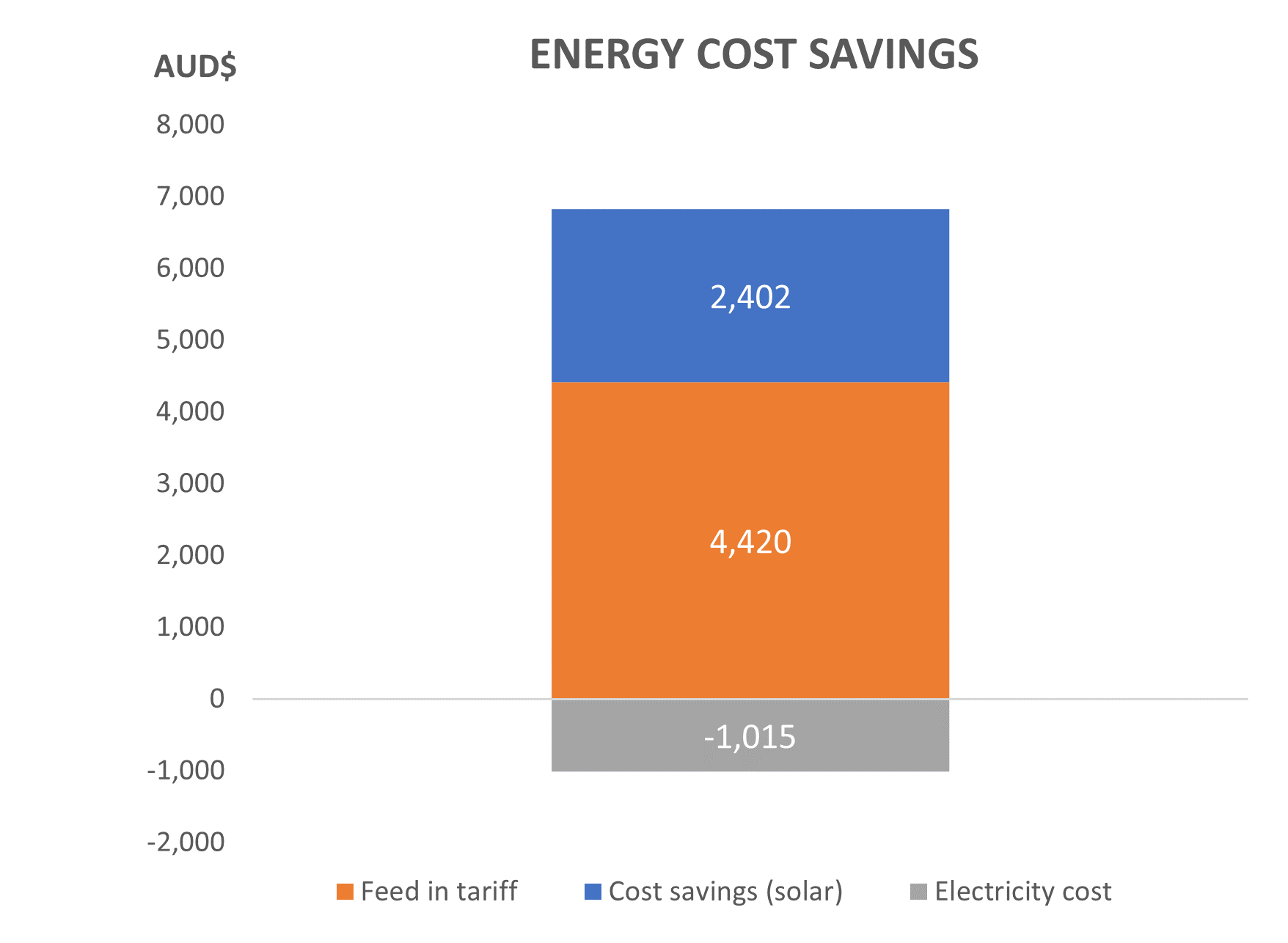

From the solar generation, only 15% or 10,329 kWh are being used onsite valued at $2,402 and 56,222 kWh are being exported to the grid with a revenue of $4,420. Part of the energy injected into the grid will be consumed onsite as the nursery expansion plans advance and production increases. Considering that 4,361 kWh – 30% of the total energy use onsite – are being imported from the grid at a cost of $1,015, there are additional potential savings from shifting consumption into the solar generation period. The total power balance of the farm, including solar exports, and the energy cost distribution, are shown in the following figures.

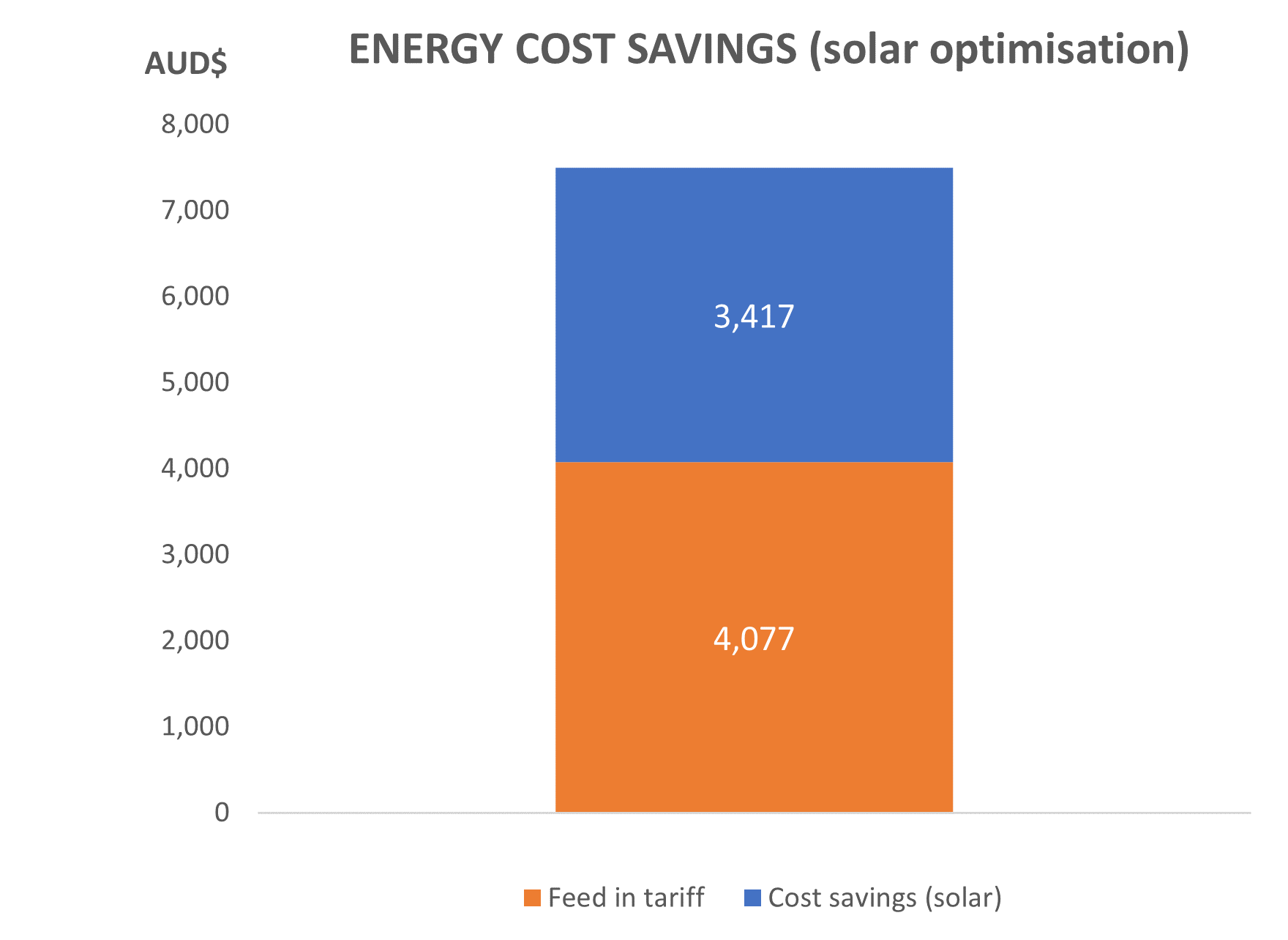

The next step for the farm is to adjust energy usage to offset as much energy consumption as possible from the grid, which would lead to further cost savings. The revenue from feeding into the grid is lower than the cost savings from using the energy onsite: for every dollar of energy exported, more than $3 could be saved if the energy were consumed onsite. If the farm were to shift 4,361kWh of energy consumption per year to coincide with solar generation times, they would save an extra $670 per year.

From the implementation of recommendations in the audit, the farm has reduced energy consumption by 453% thus becoming a net exporter of power. Costs have been reduced by 200%, including feed-in revenue, with Carbon emission savings of 53.9 t/CO2-e per year.

Table 3. Pre and post implementation energy consumption, costs, and energy productivity improvements.

| Metric | Pre-implementation (2020) | Post-implementation | Reduction (%) |

| Energy Consumption (kWh) | 14,690 | -51,861 | 453 |

| Cost ($) | 3,417 | -3,405 | 200 |

| Energy Productivity (kWh/ha) | 20,123 | -71,043 | 453 |

An energy audit is a good investment

An energy audit is a great first step in moving a business towards a more efficient future by reducing energy use, costs, and carbon emissions on site.

The Energy Savers Plus Extension Program was delivered by the Queensland Farmers Federation with support and funding from the Queensland Department of Energy and Public Works.